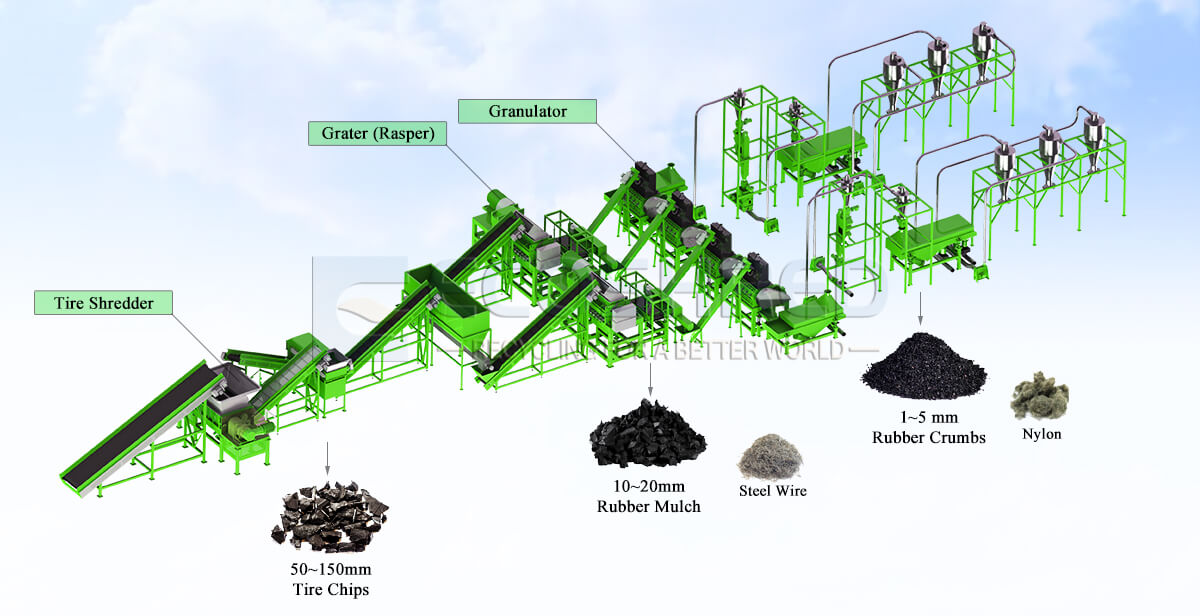

Tyre recycling plant for rubber crumb mainly contains three types of machines: tyre shredding machine, rasper and granulator.

Ecoshred Tire Granulation Line also utilize a variety of conveying and separation technologies to minimize product losses, maximize efficiency and maintain a clean operating environment.

1. Reducing them down to a clean cut chip with the shredder machine

whole tires are fed into a shredder that contains a compact knife system, that will cleanly cut the tires into pieces. The first pass through the shredder is a called rough shred, these pieces are long strips and will need to be cut further to be usable as end use products, such as tire derived aggregate (TDA) or tire derived fuel (TDF), or used for further processing. The larger strips remain on top of the classifier and will fall onto a return conveyor that takes the material back to the shredder for another pass.

2. Separating the steel from the rubber with the rasper machine

Pre-shredded tires are the feed stock for the rasper, the rasper machine does an exceptional job at ripping and pulling the steel out of the tire shred, the material discharged will fall on the vibrating conveyor to loosen the mix, then passes under a strong belt magnet which lifts the steel away from the rubber mulch, the wire free rubber is discharged and now ready for resale, the size this material ranges from 10~20mm, the rubber can now be used for mulch and playground cover,

3. Reducing the rubber crumb size with granulator and removing the nylon fiber

The clean wire free rubber mulch that is produced in stage 2 is now ready to be made into granulated crumb rubber ranging from 1~5 mm, here the rubber is being fed to the granulator machine, the rubber is now further reduced in size and is discharged onto a vibratory fiber removal screen that will agitate and screen the rubber and capture the nylon fiber, the granulated rubber falls through the screen while the fiber remains on top.

Crumb rubber have numerous uses – like rubber crumb widely used in sports field, like running track, artificial grass, playground or rubber tile which is widely used in gym, walking street, stud-farm or playground etc, many athletic fields and sporting surfaces utilize crumb rubber as a soft and absorbent layer. Also lots of rubber modified asphalt roadways and rubber sealants also use crumb rubber as a main ingredient. The recovered steel can be melted and reused. Textile has a very high effective burning value and can therefore be mixed with other materials in order to increase that material’s effective burning value.

ECOSHRED offers the most versatile options for tyre recycling. You can process all tyres and produce both shreds, chips, and granulate in varying amounts from the same plant. This ensures ultimate flexibility!

Model |

Capacity |

Output Rubber Size |

Purity |

Total Power |

Required Worker |

Required Space |

Power Consumption |

| ESG-500 | 500 kg/h | 1~5 mm | 99.9% | 257.9 kW | 2~3 people | 20*12*6 m | 180 kWh per hour |

| ESG-1000 | 1000 kg/h | 1~5 mm | 99.9% | 290.9 kW | 2~3 people | 21.3*12*6 m | 204 kWh per hour |

| ESG-2000 | 2000 kg/h | 1~5 mm | 99.9% | 486.6 kW | 2~3 people | 27*13*6 m | 340 kWh per hour |

| ESG-4000 | 4000 kg/h | 1~5 mm | 99.9% | 887.1 kW | 2~3 people | 55*13.5*7m | 532 kWh per hour |

| Note: we can customize any higher capacity than 4t/h based on customer’s requirement. | |||||||

If you have any question about tire recycling machine equipments or tire recycling product lines, Please do not hesitate to contact us. We would reply to you as soon as possible.