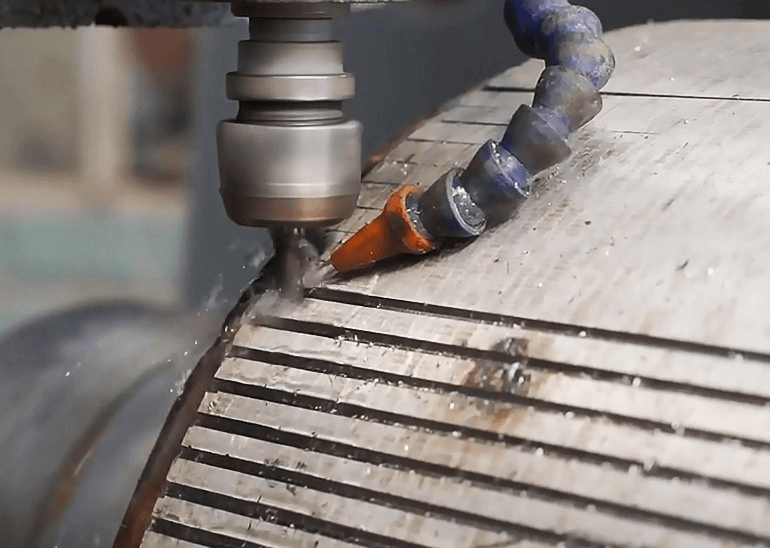

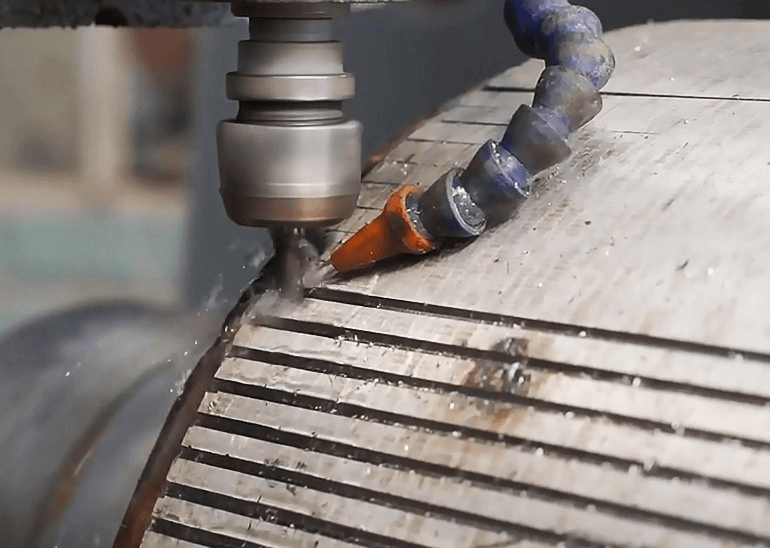

Ecoshred rubber crusher machine: composed by the decomposition of waste tire powder crushing, screening unit composed of magnetic carrier. Through the decomposition of waste tire facilities, tire processing into small pieces, and then crushing mill of the rubber block, rubber powder to be mixed wire; then powder magnetic separator, the steel and rubber powder separated completely.

Through the feeding device through two sieve beds filter out the fine material and then by magnetic roller, magnetic separation of a steel wire, Preparation of 10 mesh fineness of the purity of-40mesh powder(fineness optional).This processing technology,there is no air pollu-tion,no waste water,low operation cost.lt is the best equipment to produce waste tire rubber powder.

ECOSHRED waste tire rubber powder equipment: composed by the decomposition of waste tire powder crushing, screening unit composed of magnetic carrier. Through the decomposition of waste tire facilities, tire processing into small pieces, and then crushing mill of the rubber block, rubber powder to be mixed wire; then powder magnetic separator, the steel and rubber powder separated completely.

Through the feeding device through two sieve beds filter out the fine material and then by magnetic roller, magnetic separation of a steel wire, Preparation of 10 mesh fineness of the purity of-40mesh powder(fineness optional).This processing technology,there is no air pollu-tion,no waste water,low operation cost.lt is the best equipment to produce waste tire rubber powder.

| Model | Capacity | Output Rubber Size | Purity | Crusher Power | Required Worker | Required Space | Power Consumption |

| RCM-500 | 300~500 kg/h | 5~40 mesh | 99.7% | 55 kW | 4~5 people | 12*8*5 m | 65 kWh per hour |

| RCM-1000 | 500~1000 kg/h | 5~40 mesh | 99.7% | 110 kW | 3~4 people | 21*8*5 m | 136 kWh per hour |

| RCM-1500 | 1000~1500 kg/h | 5~40 mesh | 99.7% | 132 kW | 3~4 people | 27*8*5 m | 151 kWh per hour |

| RCM-3000 | 2000~3000 kg/h | 5~40 mesh | 99.7% | 200 kW | 2~3 people | 39*10*5 m | 223 kWh per hour |

If you have any question about tire recycling line, Please do not hesitate to contact us. We would reply to you as soon as possible.